5 Reasons to Choose SLA 3D Printing Technology

Isotropy in SLA 3D Printing

Unlike other 3D printing technologies, SLA printers can create parts with isotropic properties, meaning the material behaves consistently in different directions. This is essential for applications where uniform strength and behavior are critical. This isotropy makes SLA particularly useful for manufacturing fixtures.

Fluid Resistance

In SLA 3D printing, the model is produced in one go, including the intricate internal structures. This is vital in engineering, medical, and domestic applications where the parts may come into contact with fluids. The integral structure prevents fluid penetration, maintaining the integrity of the parts.

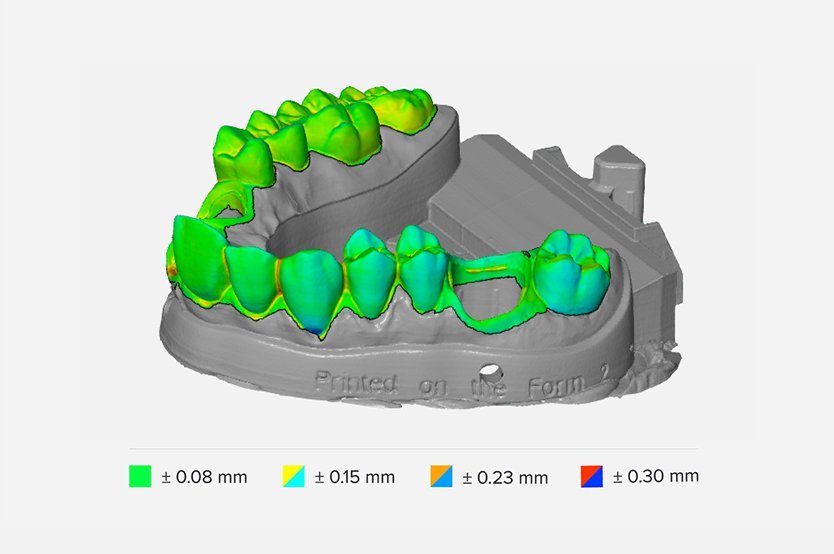

High Precision and Accuracy

Precision is especially crucial in medical and dental applications. SLA printers operate in a controlled environment and use laser instead of heat, minimizing dimensional changes due to thermal expansion and contraction. This results in increased printing accuracy, with precision ranging from 25 to 300 microns, compared to 100 to 300 microns in SLS and FDM printers.

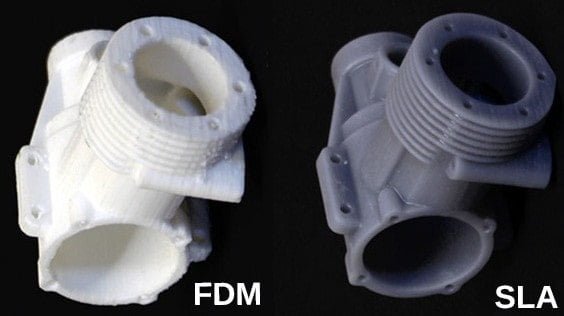

Superior Surface Quality

SLA is considered the gold standard for surface precision and smoothness, comparable to injection molding and machining. This reduces the need for post-processing like sanding and polishing. Even at the same 100-micron precision, SLA printers provide better surface smoothness due to their laser’s 85-micron accuracy, compared to the 250 to 800 microns of FDM nozzles and 350 microns of SLS.

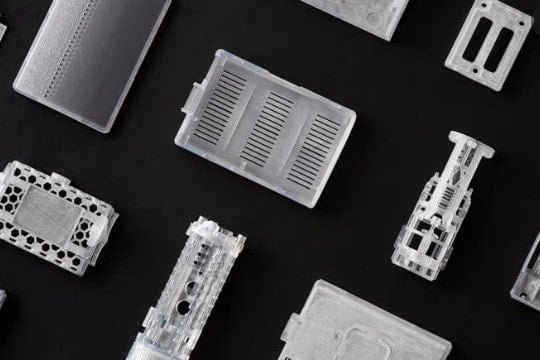

High Adaptability of Materials

SLA resins are diverse, with unique and varying properties, allowing for a wide range of applications. Printed parts can be hard or soft, have suitable mechanical properties, or be resistant to thermal shock. They can also be used in stress-bearing applications. The unique properties provided by SLA printers have made them popular for various applications.

Latest Articles in your inbox

Subscribe to our newsletter to get the newest manufacturing and industrial services articles in your inbox once a week.