what is press brake forming and how it works

Press Brake Forming is a widely used bending machine in the steel and iron industries with hydraulic functionality. It plays an unparalleled role in the processing of sheet metal, being one of the crucial equipment. This device significantly influences product quality, processing efficiency, and accuracy.

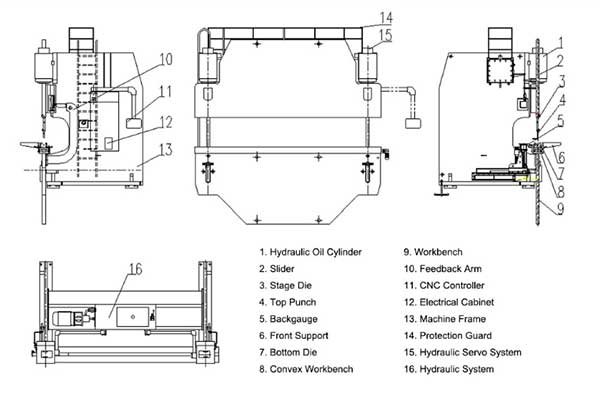

As shown in the figure below, this machine consists of a frame, a sliding block, a hydraulic system, a front loading rack, a back gauge, a mold, an electrical system, etc.

The downward vertical pressure in a hydraulic press brake is generated by two parallel hydraulic cylinders to guide the complete bending process. The hydraulic control system, acting as the brain of the press brake, primarily controls the simultaneous operation of the bending process and the position of the hydraulic cylinders when the machine is fully loaded.

Hydraulic press brakes are utilized in various industries. Their applications include the automotive sector, power generation, oil and gas, chemical materials, textiles, paper production, and other manufacturing processes. Their design is based on the principle of reciprocity. This means that when two sets of pistons exert pressure on each other, the pressure acting on them results in an equivalent compressive force to the force of each piston.

Advantages of Hydraulic Press Brakes

- Speed and Efficiency: Hydraulic press brakes offer high speed and low drag.

- Versatility: They can handle nearly any application.

- High Load Capacity: Capable of withstanding heavy loads and generating high pressure.

- Widespread Use: Widely used in various industries and increasingly replacing CNC machines in sectors like aviation.

Hydraulic press brakes can be classified into direct and indirect types. Indirect types use rotational or linear motion to apply pressure and can operate either automatically or manually. Available in different styles for various purposes, these include rotary drum, rolling, and centrifugal brake machines. They are used for tasks like loading/unloading, lifting, measuring, painting, cutting, drilling, etc.

How Press Brakes Work

The higher the tonnage of the equipment, the greater the pressure generated. This is why there are medium, small, and compact hydraulic press brakes in the market. They are more convenient compared to electric press brakes, which are harder to install and maintain. With technological advancements, lightweight hydraulic press brakes are available, relatively stronger, and help in effectively lifting and reducing tonnage.

Hydraulic press brakes are known for their reliability and durability. Available in various sizes, smaller ones are suitable for lighter, thinner materials, while larger models are required for thicker materials covering significant distances. These hydraulic machine tools use an electric motor to apply consistent pressure on moving materials, ideal for production. With technological progress, new and advanced hydraulic machines have been developed, easily available in the market to facilitate work and reduce pressure levels.

Types of Hydraulic Press Brakes Forming

There are various types of hydraulic press brakes available, tailored to their specific applications. Some common types include:

- Vacuum Press Brakes Forming: These press brakes function by applying a vacuum to exert force. They are suitable for specific applications where precision and control are paramount.

- Drum Brake Mechanism Press Brakes Forming: Utilizing a drum brake mechanism, these press brakes apply pressure for bending operations. They are versatile and can be used in various industrial applications.

- Different Power Levels and Sizes: Hydraulic press brakes come in various sizes and power levels to suit different industrial needs. Smaller models are ideal for operations requiring maximum tensile strength on a smaller scale, while larger models are suited for high-tensile-strength applications.

- Servo-Electric Press Brakes Forming: These specialized presses are designed for high-speed, detailed applications where high pressure is necessary. They offer precision and efficiency, especially in intricate bending tasks.

Each type of hydraulic press brake offers unique benefits, making them suitable for a range of applications across different industries. The choice of a press brake depends on the specific requirements of the bending process, such as the material’s thickness, the degree of bending needed, and the production volume.

Materials Used in the Construction of Hydraulic Press Brake Systems

Hydraulic press brakes are made from various materials depending on their application and environment. Steel, aluminum, cast iron, and bronze parts are used in situations where heavy compressive braking is needed. Cast iron and bronze hydraulic pistons are available in different sizes and are suitable for various types of press brakes.

In addition to the above, there are several hydraulic pumps for use in press brake applications. Common types of hydraulic pumps include rotary pumps, screw pumps, rotary vane pumps, and rotary valve pumps. The hydraulic fluid enters the system through an air intake valve and is directed towards discharge through a hose. The entire system and its components are enclosed in a pump chamber to prevent unwanted fluid flow.

Features of the Press Brake Machine

- Equipped with a CNC numerical control system for precise adjustments.

- Capability to store different programs for bending various types of sheets.

- Strong and stable structure to apply high pressure to metal sheets.

- Includes various tools and matrices for bending sheets into different shapes.

- Ability to work with metal sheets of various thicknesses.

- Applicable in various industries including automotive, metal structure fabrication, electronic parts manufacturing, etc.

Capabilities of the Press Brake Machine

- Bending and shaping metal sheets into various forms, including U-Shape, V-Shape, Box-Shape, etc.

- Ability to work with metal sheets of various thicknesses.

- High precision and accuracy in bending and shaping sheets using a CNC numerical control system.

- Capability to work with a high volume of metal sheets in a short amount of time.

- High safety for the user with the use of intelligent safety systems.

Applications of the Press Brake Machine

- Manufacturing automotive parts, including door panels, chassis, etc.

- Constructing structural and building components, such as metal doors and windows, bridges, etc.

- Producing electronic components.

- Fabricating aerospace parts.

- Manufacturing household appliances, like refrigerators, washing machines, etc.

- Producing military and defense components.

Latest Articles in your inbox

Subscribe to our newsletter to get the newest manufacturing and industrial services articles in your inbox once a week.

kinard gibble

hart cuperus

johnjack recha