what is Grinding?

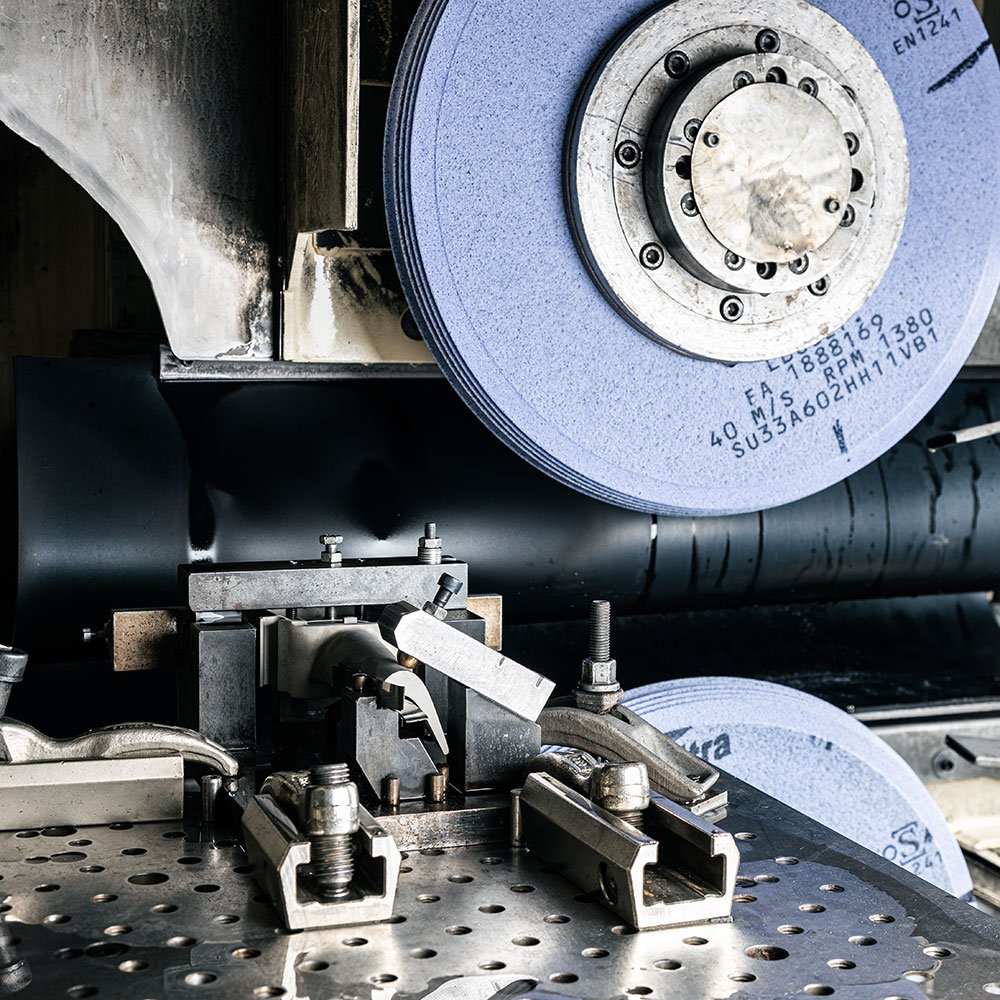

Grinding is a material removal process that accomplishes the removal of excess material on a workpiece through abrasion. Each of the abrasive grains on the surface slightly alters the shape of the workpiece. Typically, grinding is the final stage of work on a piece, after which the surface quality is improved, essentially a type of surface finishing.

The process of sharpening and correcting the angles of the grinding wheel, as well as cleaning its surfaces from materials that have adhered to them, is called dressing. All grinding wheels, except for plated ones, need dressing.

During grinding operations, the primary cutting motion can be applied to either the workpiece or the tool, depending on their geometry. The grinding environment consists of hard particles like silicon carbide or alumina bonded together with a binder (matrix). Since the size of the hard particles varies within a range and these particles are usually randomly oriented within the matrix, defining the thickness of the undeformed chip for each cutting edge is often difficult, but it generally varies between approximately 0.025 to 0.00025 millimeters.

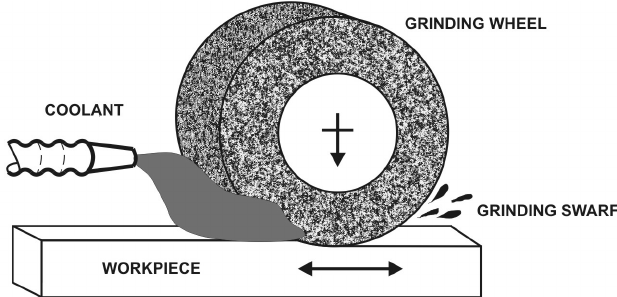

A grinding machine includes a motor that rotates the grinding stone at the required speed and a bed to hold the workpiece in a fixture. The grinding head can be adjusted to be stationary or movable for the workpiece. During the grinding operation, the machine also generates considerable heat; hence, cooling is required to prevent the temperature from exceeding the tolerance of the workpiece. Even the coolant can burn in some cases. In high-precision grinding, about 200 nanometers of heat is produced, which does not require cooling.

Different types of Grinding process

Surface grinding

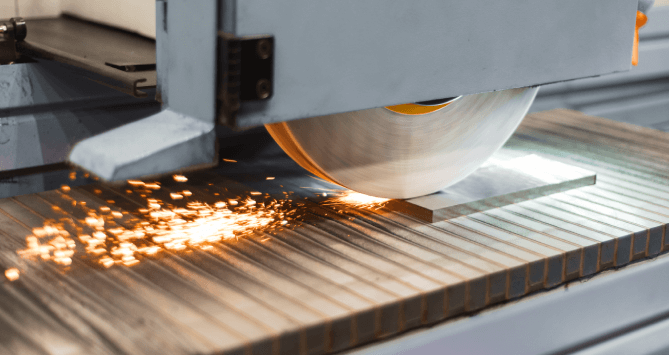

Surface grinding is a machining process used to produce a smooth finish on flat surfaces. It involves a rotating abrasive wheel that grinds the surface of a workpiece to achieve the desired flatness and smoothness. The process is commonly used in the manufacture of metallic and nonmetallic materials. In this process, the workpiece is secured on a table that moves back and forth under the rotating abrasive wheel. The depth of cut is usually very small, and the grinding wheel is often dressed to maintain its shape and sharpness. Surface grinding can produce very precise surfaces and is typically used for finishing work, giving the material a high level of surface integrity and dimensional accuracy. This method is widely used in industrial applications, particularly in the automotive, aerospace, tool and die, and other manufacturing industries, where precise surface finishing is crucial.

Centerless grinding

Centerless grinding is a machining process that removes material from the outside diameter of a workpiece, using abrasive cutting. Unlike traditional grinding methods where the workpiece is secured between two centers or chucked, in centerless grinding the workpiece is supported on its own outer diameter by a workblade and is rotated by a regulating wheel. This wheel is typically angled to provide a feed through which the workpiece is driven, while a larger abrasive grinding wheel removes material from the workpiece. Centerless grinding is known for its ability to achieve high levels of precision and smooth surface finishes on cylindrical parts. The process is efficient for mass production of parts with consistent roundness and tight tolerances, and is commonly used in the manufacturing of components for the automotive, aerospace, and medical industries. Its effectiveness in processing long and slender parts that could be distorted or deformed when clamped in other grinding methods makes it particularly valuable in certain industrial contexts.

Cylindrical grinding

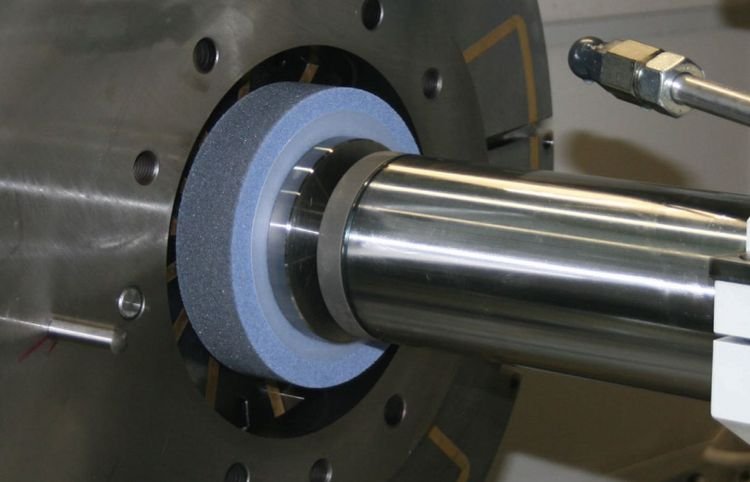

Cylindrical grinding is a machining process used to finish the external or internal surfaces of cylindrical workpieces. This process involves a rotating grinding wheel that removes material from the surface of a cylindrical workpiece that is rotated on an axis. Cylindrical grinding can be divided into two types: external cylindrical grinding, where the workpiece is held between centers or in a chuck and rotated against the grinding wheel, and internal cylindrical grinding, where the grinding wheel is smaller than the bore of the workpiece and grinds the internal surface. This method is ideal for achieving high precision and fine surface finishes on cylindrical parts, such as rods, shafts, and bearing races. It’s particularly useful for components that require precise concentricity or surface smoothness. The precise control of the grinding process makes it suitable for manufacturing a variety of parts in automotive, aerospace, and other industrial sectors, where tight tolerances and high-quality surface finishes are essential.

Creep-feed grinding

Creep-feed grinding is a specialized machining process primarily used for producing deep cuts and complex shapes in hard-to-machine materials. This process, unlike conventional grinding that uses shallow depths of cut and high feed rates, involves a much deeper depth of cut and a significantly slower feed rate. In creep-feed grinding, a large area of the grinding wheel is in contact with the workpiece, resulting in a high material removal rate and a significant reduction in heat generation. This method is particularly effective for shaping high-strength alloys, superalloys, and ceramics, where other machining processes might be inefficient or cause thermal damage to the workpiece. Creep-feed grinding is highly efficient for producing precise, complex profiles and contours in a single pass, eliminating the need for multiple grinding passes and reducing overall machining time. It is widely used in the aerospace, automotive, power generation, and tool and die industries for manufacturing turbine blades, gear profiles, and other intricate parts.

Latest Articles in your inbox

Subscribe to our newsletter to get the newest manufacturing and industrial services articles in your inbox once a week.