what is End Milling?

End milling is a versatile and widely-used machining process in which a rotary cutting tool, known as an end mill, is used to remove material from a workpiece. This process is carried out on a milling machine, and it is a fundamental technique in the manufacturing industry for shaping and cutting materials ranging from metals to plastics and composites.

Key Characteristics of End Milling:

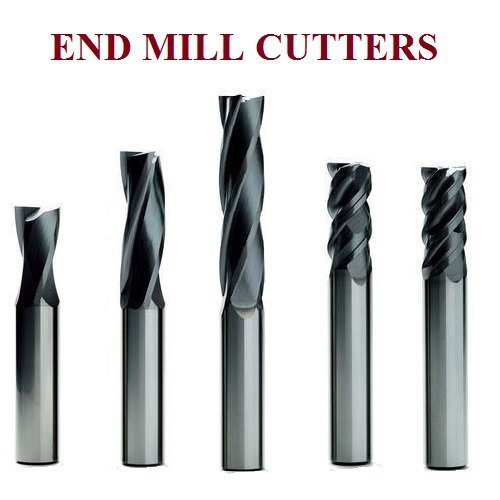

The End Mill Tool: End mills are cutting tools with cutting teeth on both the end face of the cutter and the sides. They come in a variety of shapes and sizes to cater to different milling needs. Common types include square end mills, ball nose end mills, and corner radius end mills.

Cutting Action: Unlike drill bits, which cut only at their tip, end mills can cut in all directions. They can move laterally (sideways) to create shapes, profiles, and cavities in the workpiece.

Versatility in Operations: End milling is used for a broad range of operations such as slotting, profiling, contouring, counterboring, and plunging. It can produce a variety of features like pockets, slots, and complex contours.

Materials: End mills can be made from high-speed steel (HSS), cobalt steel, carbide, and other materials optimized for specific applications and materials to be machined.

Machining Capabilities: End milling is capable of producing fine finishes and precise cuts. It’s used for roughing (removing large amounts of material quickly) and finishing operations.

Machine Compatibility: End mills are used on both manual and CNC milling machines. They are held in place with a tool holder or collet and can be changed depending on the specific task.

Types of Cuts: End mills can perform peripheral (side) milling and face (end) milling. Peripheral milling removes material around the circumference of the end mill, while face milling removes material from the end.

Coolant Use: Depending on the material and cutting conditions, coolant or lubricant may be used to reduce heat and extend tool life.

Applications: End milling is used in manufacturing a wide range of products, from small components to large parts. It’s crucial in automotive, aerospace, mold-making, and metalworking industries.

Skill and Precision: While CNC milling offers precision and repeatability, skilled operators are required to set up and oversee the milling process, even when automated equipment is used.

End milling is a fundamental and flexible machining process in the manufacturing industry, known for its efficiency in creating complex shapes and high-precision parts. Its wide range of applications, ability to work with various materials, and compatibility with different types of milling machines make it an indispensable technique in modern manufacturing. Whether for prototyping, custom manufacturing, or large-scale production, end milling plays a critical role in creating components across numerous industries.

Latest Articles in your inbox

Subscribe to our newsletter to get the newest manufacturing and industrial services articles in your inbox once a week.