Advantages and Disadvantages of SLS 3D Printers

Advantages of Using SLS 3D Printers

Here we mention the most important advantages of SLS 3D printers:

- Range of Printable Materials One of the most significant advantages of SLS 3D printers is the variety of printable materials. These materials possess characteristics such as strength, durability, and high performance, unlike the FDM method, which is often used for prototyping.

- No Need for Support Structures As mentioned above, one of the main advantages of SLS 3D printers is the lack of need for support structures for parts with negative angles. This advantage not only improves the quality of the printed piece but also prevents the wastage of consumable materials.

- High Printing Speed One of the fastest 3D printing methods is SLS, as the laser simultaneously impacts all points across the surface of the layer, building all points at once. Additionally, unlike SLA 3D printers, there is no need for post-printing operations to dry the piece.

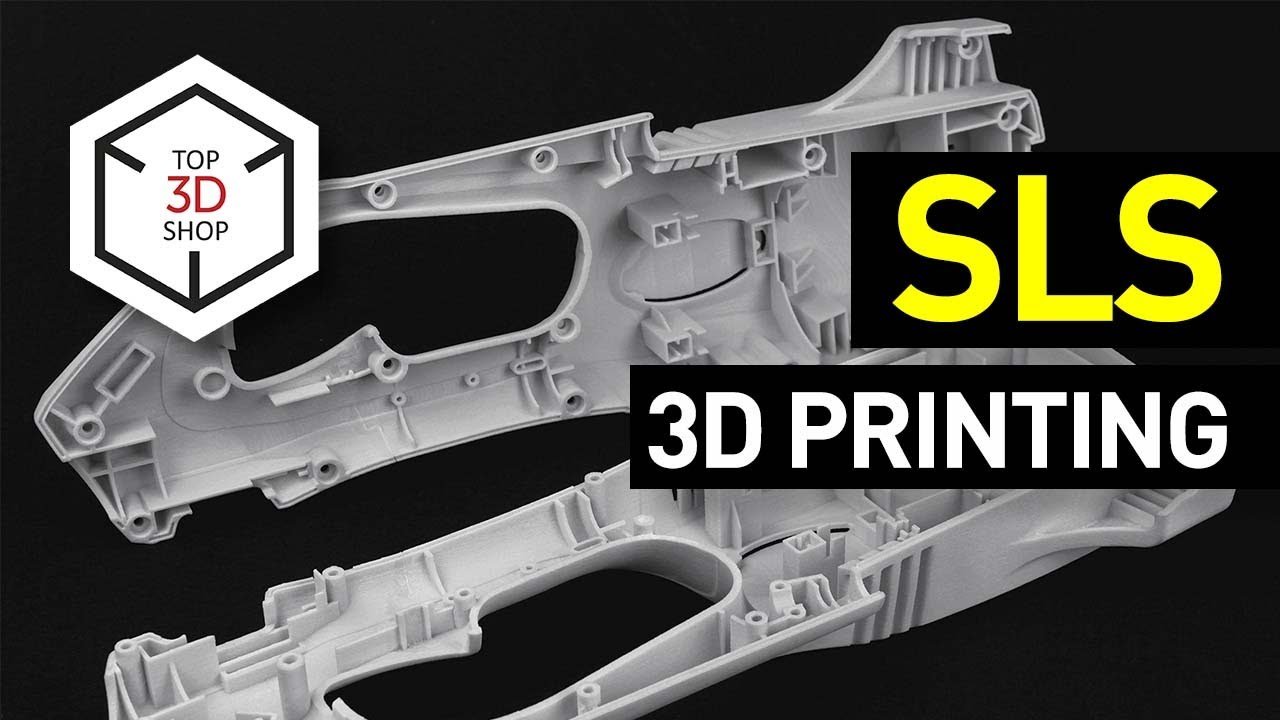

- Complex Part Construction SLS 3D printers are among the most precise 3D printers that can print workpieces with high quality and precision, regardless of their complexity. Even the tiniest details, such as millimeter-sized holes, can be created without issue.

- High Quality of Printed Parts One of the very important advantages of SLS 3D printers is the high strength and hardness of the parts that have been 3D printed using this method.

- Suitable for Production Parts Considering all the mentioned advantages, such as the ability to create complex parts and the quality and strength of the printed parts, SLS 3D printers can be used for production parts. Therefore, these printers can be utilized for limited-edition production runs.

Disadvantages of Using SLS 3D Printers

Two major drawbacks of SLS 3D printers are their high cost and large size.

- High Cost of Printer and Laser The significant expense of SLS 3D printers and the high production cost of parts printed using the SLS method make these devices less prevalent compared to FDM printers.

- Large-size SLS 3D printers usually have very large dimensions and are considered industrial machines. Therefore, they are not suitable for home use due to their size.

Latest Articles in your inbox

Subscribe to our newsletter to get the newest manufacturing and industrial services articles in your inbox once a week.