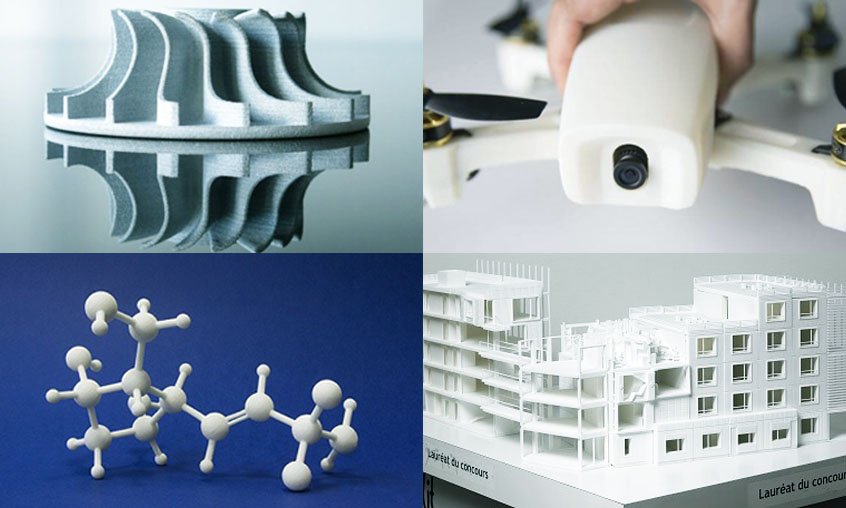

Applications of 3D printing in various industries

The origin of 3D printing is found in “rapid prototyping” and the principles of industrial prototyping, aimed at accelerating the initial stages of production in a fast and simple way, which allows for the repeated production of a product to achieve higher efficiency and speed in an optimized product. This saves time and money at the beginning of the overall development process of a product and ensures the equipping of the production process. Today, despite often being overlooked, rapid prototyping may still be the biggest application of modern 3D printing.

Considering the necessity of 3D printing for rapid prototyping, the developments and improvements that have occurred in the process and the materials used have reduced the production process chain. Applications of molding and casting have evolved by taking advantage of the benefits of various developed processes. These applications are increasingly adopted and used across various industrial sectors.

Similar to final manufacturing operations, improvement operations continue to simplify implementation.

Applications of 3D printing in various industries

Medicine and Dentistry

The medical field, not only as one of the earliest adopters of 3D printing, is also seen as an area with tremendous potential for growth. This is due to the customization and personalization capabilities of this technology, as well as the potential to improve human quality of life by advancing processes and developing materials to meet medical standards.

The application of 3D printing in medicine and dentistry encompasses a wide range of services. In addition to improving prototyping methods to support the development of new products for the medical and dental industries, these technologies have been used to create patterns for dental crowns using Downstream Metal Casting and in the production of tools that use plastic to create dental aligners in a vacuum. This technology has the advantage of manufacturing stock products (parent products or non-custom products), such as hip and knee joint implants, and custom products tailored for each patient, such as hearing aids, orthotic insoles for shoes, single-use implants, and personalized prosthetics for patients with conditions such as osteoarthritis, osteoporosis, and cancer, as well as products needed for accident victims and trauma defects. Surgical guides produced via 3D printing for specific surgeries are also a growing application that assists surgeons in their work and patients in their recovery process. Moreover, technology has been developed for 3D printing skin, bone, tissue, pharmaceuticals, and even human organs.

Aerospace

Similar to the medical field, the aerospace industry was one of the first to utilize 3D printing technologies, benefiting from the earliest forms of these technologies for product development and prototyping. These companies, often in collaboration with research and scientific institutions, are at the cutting edge of science or shifting the boundaries of these technologies for manufacturing and production applications. The application of 3D printing in aerospace is significant due to the ambitious and technology-driven nature of this sector.

Given the critical nature of airplane development, R&D is highly demanded and stringent, standards are vital, and industrial 3D printing systems are progressing in this direction. The development of materials and processes has witnessed the expansion of many key applications for the aerospace industry. Some non-critical parts are currently being used in airplanes, and major aircraft manufacturers such as Airbus and Boeing have signed substantial contracts with companies active in additive manufacturing.

Some of the most well-known companies in the aviation industry that have turned to additive manufacturing include GE/Morris Technologies, Airbus/EADS, Rolls-Royce, BAE Systems, and Boeing.

Automotive

The automotive industry is also one of the first industries to widely use 3D printers. Many automotive companies, especially in the sports cars and Formula One segments, have followed a path similar to aerospace companies. Initially, automotive companies used additive manufacturing technologies only for rapid prototyping. However, today the application of 3D printing in the automotive industry is not limited to rapid prototyping, and these companies have turned to 3D printers for the manufacture of final parts (components that are directly placed in vehicles).

Now, many automotive companies are looking to exploit the potential of 3D printing for their post-sales services. For example, Porsche recently started producing spare parts for its classic cars in limited quantities using 3D printers.

Jewelry Making

Traditionally, the process of designing and making jewelry has always required high levels of expertise and knowledge in specialized fields such as mold making, casting, electroplating, forging, silver/gold metalworking, gem cutting, engraving, and polishing. Each of these areas has evolved over many years and requires a high level of technical knowledge to be applied in jewelry making. For example, the history of precision casting dates back 4,000 years.

The application of 3D printing in jewelry making is such that it can completely influence other active technologies used in this field. There is considerable attention on how 3D printing can further develop this industry. From new design freedoms created by 3D printing and 3D CAD and the improvement of traditional processes for jewelry production to products that are directly made with 3D printers and eliminate many stages of traditional methods; additive manufacturing has had an incredibly remarkable impact on the field of jewelry making.

Art/Design/Sculpture

Artists and sculptors are being attracted to 3D printing in thousands of different ways to achieve forms and actions that were not possible in the past. This field, as a highly active area, is constantly finding new ways to work with 3D printing technologies and present their results to the world. Currently, many artists have made a name for themselves by working with 3D modeling technologies, 3D scanning, and 3D printing. Artists who have become aware of the application of 3D printing in art and have benefited from it include Joshua Harker, Dizingof, Jessica Rosenkrantz, Pia Hinze, Nick Ervinck, and Lionel Dean.

The field of 3D scanning, in connection with 3D printing, has added a new dimension to the world of art. However, artists and students are now following a proven method that involves reproducing the work of past masters and creating accurate copies of ancient sculptures.

Architecture

Architectural models have long been one of the fundamental applications of 3D printing for producing models that represent the precise dimensions of an architectural vision. 3D printing provides a relatively quick, easy, and economically viable method for directly producing accurate models from 3D CAM, BIM, or other digital information used by architects. Many successful architectural firms currently use 3D printing (internally within the company or as a service) as a vital part of their workflow to enhance innovation and improve communication. The application of 3D printing in architecture looks to even more ambitious horizons.

Recently, some theoretical architects have viewed 3D printing as a direct construction method. Extensive research is being conducted in this area by technology institutions such as Loughborough University, Contour Crafting, and Universe Architecture.

Fashion

With the advancement of 3D printing technologies in terms of resolution and more flexible materials, an industry known for its experiments and bold statements has entered the field of 3D printing. We are certainly talking about fashion!

Accessories such as shoes, tiaras, hats, and bags produced by 3D printing have found their way to the global roads. Even some theoretical fashion designers have demonstrated the capacity of this technology for use in high-end fashion, dresses, cloaks, full-length robes, and even some undergarments that have been showcased in various fashion halls around the world.

Special mention should be made of Iris van Herpen as a pioneer in this field. She has produced many collections, modeled in Paris and Milan catwalks, by blending 3D printing with natural laws that did not exist in the past in fashion design. Many people have followed in her footsteps and will continue to do so, often with quite similar results. Also, with big companies like Nike entering the field of 3D printing in the fashion industry, we should expect major transformations in the fashion industry in the near future.

Food

Although the food industry has recently entered the realm of 3D printing technology users, this field is one of the growing uses of the 3D printing industry that has amazed people and has tremendous potential to truly lead this technology down its main path. Additionally, we all always need to eat! 3D printing is emerging as a new method for preparing and presenting food.

The application of 3D printing in the food industry was initially limited to simple uses. The first steps of 3D food printing were done on chocolate and sugar. After this, specialized 3D food printers quickly developed and entered the market. Some of the first experiments in this field have been 3D printing of meat at the cellular protein level. Pasta has been the latest food group studied for 3D food printing.

Looking to the future, 3D printing can be seen as a complete method for food preparation and also a way to balance nutrients in a comprehensive and healthy way.

Latest Articles in your inbox

Subscribe to our newsletter to get the newest manufacturing and industrial services articles in your inbox once a week.