The components of a Wirecut machine

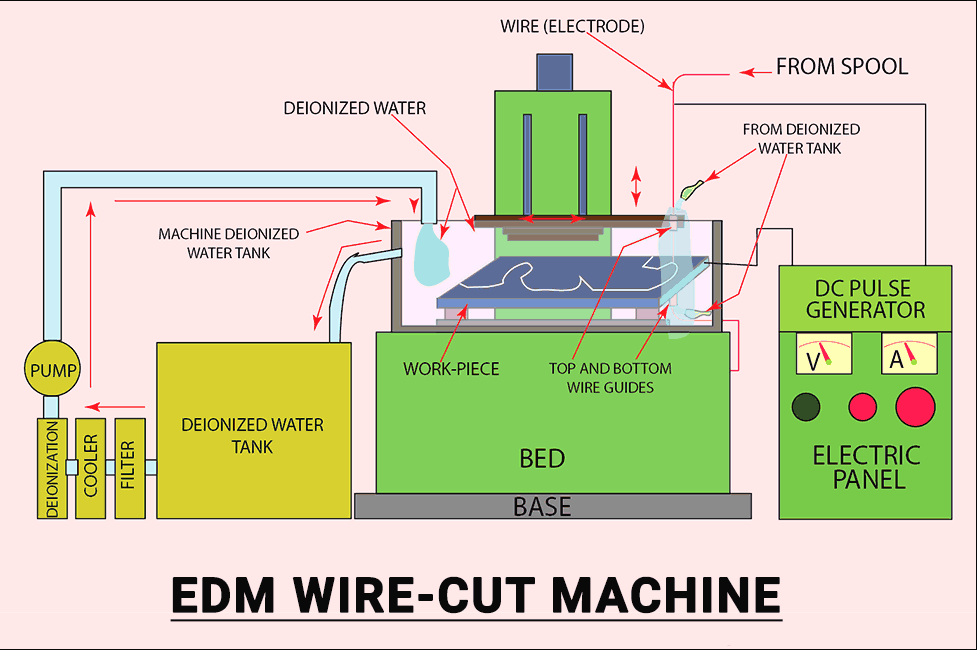

Conductive Wire (Wire Electrode): A metallic wire with a small diameter and high resistance, which moves with high precision and adjustable speed in the machine. This wire is used for cutting parts at precise and complex points.

Deionized Water Tank: The wirecut machine contains a tank for deionized water or solution. This liquid, created by the electric spark between the conductive wire and the workpiece, facilitates the cutting process while maintaining the speed of the wire and dissipating the heat generated in the process.

Controller (Controller Panel): The wirecut machine features a control unit responsible for managing the movement of the conductive wire, the electric current, and the cutting speed. This controller operates through Computer Numerical Control (CNC) systems and is programmed using specific software.

Work-piece: The work-piece or machinable piece is the item intended to be cut or shaped in the wirecut machine. This piece can be made of metal or non-metal and may include structural parts, precision components, complex pieces, or three-dimensional parts. The work-piece is usually placed on the worktable of the wirecut machine and fixed with a fixture to be positioned cylindrically or flatly in various axes. The piece must be correctly positioned in the right orientation and axis to allow for precise and uniform cutting.

Worktable: The wirecut machine has a worktable that securely holds the work-piece. This table can move in various axes to position the work-piece correctly for cutting.

Spark Generator: The wirecut machine includes a spark generator that produces the electrical ignition and spark between the conductive wire and the work-piece. This electric spark facilitates the cutting process and the removal of the desired parts of the work-piece.

Filtration System: With the creation of the electric spark between the conductive wire and the work-piece, metallic particles and debris from the cutting process accumulate in the liquid tank. The filtration system is responsible for purifying the liquid from these particles, allowing the deionized water or solution to be reused.

Water and Electrical Control: The wirecut machine uses water and electrical control systems to manage the flow of water and electricity between the conductive wire and the work-piece. These systems maintain a precise balance of electric current and water between two control valves.

The wirecut machine, with these components, is capable of performing precise and complex cuts on both metallic and non-metallic parts.

Latest Articles in your inbox

Subscribe to our newsletter to get the newest manufacturing and industrial services articles in your inbox once a week.