what is Aluminum Anodizing?

Aluminum anodizing is a process in which an oxide layer is formed on the surface of this metal, increasing its hardness, corrosion resistance, creating a decorative appearance, and altering some of its physical properties. This process can be applied to different materials, but due to the widespread applications of aluminum, aluminum anodizing is very well-known.

The general mechanism of this process is that a direct electric current is passed through a suitable electrolyte solution, where aluminum acts as the anode and another suitable metal acts as the cathode. Under these conditions, a thin layer of oxide is formed on the surface of the aluminum, the thickness of which depends on various factors.

It’s important to note that aluminum also oxidizes under normal conditions, such that in the presence of air, a non-porous layer of oxide usually forms on the surfaces of aluminum parts, which serves to protect the metal’s surface in the environment. However, the advantage of the oxide layer created in the anodizing process over natural conditions is its greater corrosion resistance.

Simply put, aluminum anodizing means electroplating aluminum sections, making this metal harder and more resistant.

Oxide Coating Steps

Electrochemical or anodic method: In specific and controlled conditions, metal oxide is produced, and a dense, impermeable oxide (aluminum anodizing) is formed. Chemical method: Creating a thick and stable layer on the metal oxide (chromate conversion).

Aluminum Anodizing Process

Anodizing is a method for altering the chemical properties of metal surfaces and other surfaces. Anodizing helps metal surfaces become resistant to corrosion, improves their aesthetic qualities, and makes them resistant to scratching.

It is also one of the most durable methods for finishing metal surfaces. Anodizing can be done on various materials, but given the focus of Digi Alum in this article, we intend to discuss the aluminum anodizing process.

Eight important questions about aluminum anodizing

What is the aluminum anodizing process?

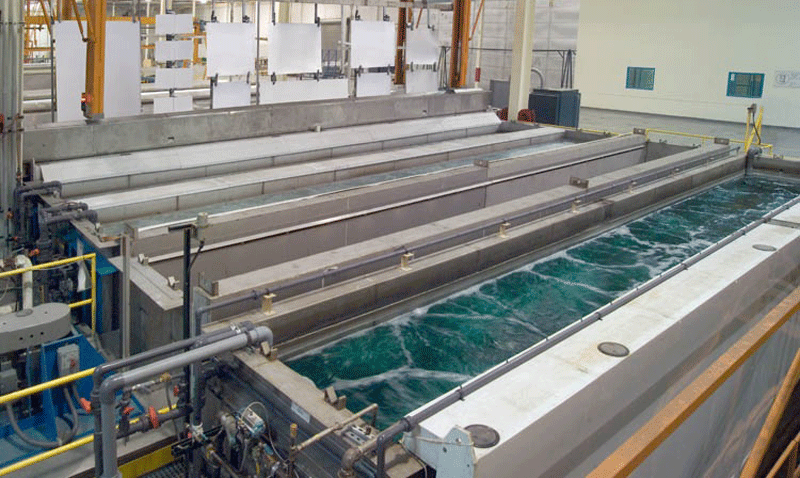

Aluminum is first subjected to thorough cleaning and washing processes to prepare it for anodizing. It is then immersed in an electrolyte solution, like sulfuric acid. The electrolyte solution, filled with many positive and negative ions for current conduction, acts as a conductor of electricity.

A positive electric charge is applied to the aluminum, turning its surface into an anode, and the negative charge is transferred to suspended plates in the electrolyte solution. The establishment of electric current in this circuit causes positive ions to be attracted to the negative plates, and negative ions to move towards the positive anode, which is the aluminum piece.

What is the barrier layer in anodizing?

The electrochemical reaction mentioned creates a series of holes or pores on the surface of the aluminum due to the escape of excess positive ions. These pores form a regular geometric pattern and penetrate into the material. The surface of the aluminum reacts with negatively charged oxygen ions, forming aluminum oxide. This thin layer is called the barrier layer, acting as a defensive barrier against chemical reactions at these points.

As the applied current continues, the areas around the pores, which are relatively weak and reactive, penetrate deeper into the aluminum and form a series of column-like hollow structures. The longer the current continues, the deeper the penetration will be.

For ordinary coatings that are not too hard or resistant, the penetration depth reaches up to 10 micrometers. When it reaches a depth of 10 micrometers and coloring is required, the process is stopped, and the aluminum surface can be completely sealed simply by washing in water.

This process forms a natural and very hard layer of aluminum oxide that can resist chemical attacks and scratching to a great extent. Aluminum oxide has a Mohs hardness scale rating of 9 out of 10, meaning it’s second only to diamond.

What is hard anodizing?

Hard anodizing, sometimes referred to as Type III, is used in harsh and unconventional environments or in mechanical parts that have a lot of friction with each other. It creates a very high resistance against wear and corrosion.

This anodizing method continues to apply electric current until the depth of the created pores exceeds 10 micrometers, reaching 25 micrometers or even more. This process takes longer and costs more, but the final result is excellent.

Does aluminum need protection against corrosion?

Although aluminum does not rot, it deteriorates and loses quality in the presence of oxygen, a process known as oxidation.

What is oxidation? Oxidation means reacting with oxygen. Oxygen is very reactive and immediately forms various compounds with other elements. Aluminum exposed to air quickly forms a layer of aluminum oxide on its surface, which provides additional protection against corrosion.

Aluminum must also be resistant to factors beyond pure air and water. Damage from acid rain, saltwater, and other pollutants can be weaknesses of aluminum in inactive surface areas. Even modern alloys differ from each other in terms of their reaction to these environmental factors, from minor surface discoloration to mechanical damage.

How is color added to anodized aluminum?

One of the first things that comes to mind when thinking about the anodizing process is colored aluminum! The stable pores created on the surface of aluminum are excellent for adding color or dye.

The dye fills the pores up to the surface of the aluminum and then the pores are completely sealed. For this reason, anodized colors are very durable and cannot be scratched off the surface of the aluminum because they have penetrated deep into the metal and can only be removed by sanding the metal surface.

Why does anodized aluminum have a shiny property?

After coloring, anodized aluminum acquires a metallic appearance. This is influenced by two factors. The first factor is due to the homogenous electrochemical etching that leaves a rough and hard surface. The deeper the created pores, the harder and rougher the metal surface, but conversely, the more stable the color of the aluminum.

The second factor is the interaction of light with the surface of the aluminum, which reacts slightly with the dye and also with the undyed metal surface. Therefore, the light that is reflected and reaches your eyes is a combination of two different wavelengths resulting from reflection from almost different surfaces. This factor creates the special shiny appearance of aluminum.

Is the anodizing process applicable to materials other than aluminum?

Yes, the anodizing process applies to metals like magnesium, titanium, and even conductive plastics. Anodizing is an affordable process and creates great durability for the metal. Therefore, this process is used to strengthen architectural connections, which are aesthetically pleasing and almost invulnerable to weathering effects.

Why can’t an entire piece be anodized?

In the anodizing process, the piece in question must be placed in a series of chemical baths. Holding this piece in a specific position requires suspending it with some type of hanger to prevent it from falling to the bottom of the tank.

The holding part, in contact with any area of the piece, will block that area, and the anodizing chemicals will not act on it. Therefore, designing a part of the piece that is suitable for holding and, at the same time, does not have an unfavorable impact on aesthetics is very clever.

Latest Articles in your inbox

Subscribe to our newsletter to get the newest manufacturing and industrial services articles in your inbox once a week.