what is Chamfer Milling?

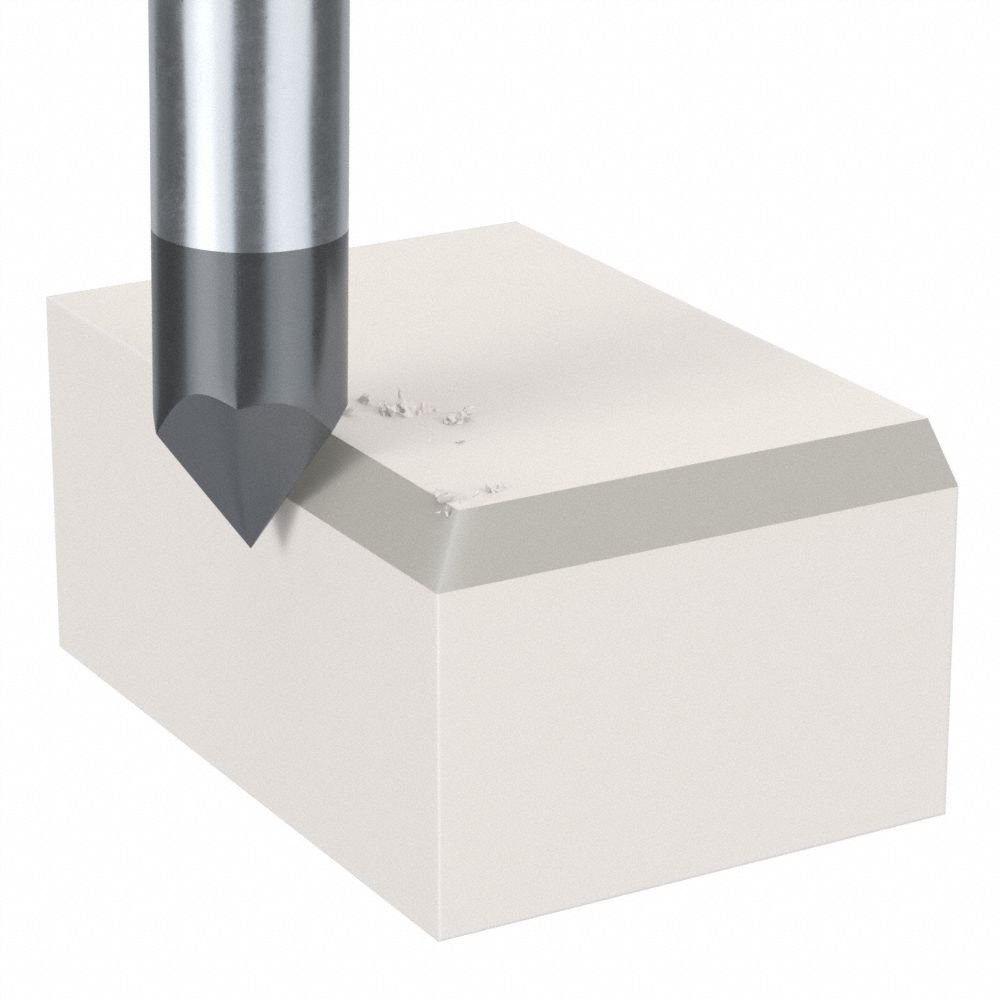

Chamfer milling is a machining process that involves the use of a chamfer mill or a chamfering tool to create a beveled edge or a chamfer on a workpiece. This technique is often employed in the manufacturing and metalworking industries to remove sharp edges, create a sloped surface, or prepare a part for subsequent processes like welding or assembly. The chamfered edge not only improves the aesthetics of the part but also enhances its safety and functionality.

Key Aspects of Chamfer Milling:

Chamfer Mill Tool: A chamfer mill is a type of cutting tool designed specifically for creating chamfers. It typically has a conical shape with a cutting angle that corresponds to the desired chamfer angle on the workpiece.

Versatility: Chamfer mills can be used to create chamfers of various sizes and angles. They are compatible with a range of materials including metals, plastics, and wood.

Functionality: The primary function of chamfer milling is to create a beveled edge at a specific angle, which can range from a slight bevel to remove a sharp edge, to a more pronounced angle for specific functional or aesthetic purposes.

Deburring: Chamfer milling is often used as a deburring process, removing burrs and sharp edges that result from previous machining operations, thereby enhancing the safety and handling of the part.

Improved Fit and Assembly: Chamfers can facilitate easier assembly of mechanical parts, as beveled edges align more easily and reduce the likelihood of component damage during assembly.

Surface Finishing: Beyond functional purposes, chamfer milling can be used to enhance the visual appeal of a part, giving it a more finished and professional look.

Milling Machines: Chamfer milling can be performed on various types of milling machines, including manual mills and CNC (Computer Numerical Control) machines, providing versatility in application.

Tool Materials: Chamfer mills are made from a variety of materials such as high-speed steel (HSS), carbide, and cobalt, chosen based on the material of the workpiece and the specific requirements of the milling operation.

Applications: This process is widely used in industries like automotive, aerospace, mold-making, and general machining for both aesthetic and functional purposes.

Precision and Control: The process requires precision and control to ensure that the chamfer is uniform and meets the specified dimensions and angles.

Chamfer milling is a critical process in the manufacturing industry, known for its ability to create clean, beveled edges that enhance the functionality, safety, and appearance of machined parts. Its wide range of applications and ability to work with different materials make chamfer milling a valuable and versatile technique in modern manufacturing and metalworking.

Latest Articles in your inbox

Subscribe to our newsletter to get the newest manufacturing and industrial services articles in your inbox once a week.