what is counterboring and its applications?

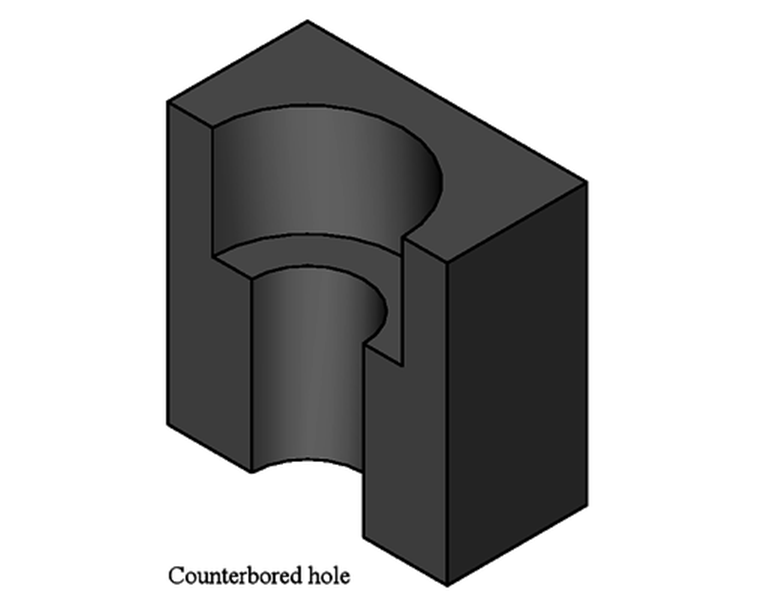

Counterboring is a machining process used to enlarge a hole to a specific diameter and depth, creating a flat-bottomed cavity at the end of or along the hole. This process is often employed to prepare a hole to accommodate a bolt head or a nut so that it sits flush with or below the surface of the workpiece. The key characteristics and applications of counterboring include:

- Purpose and Design: Counterboring is primarily used to ensure that fasteners like bolt heads or nuts can be recessed into the material, providing a smooth surface finish. It’s also used to correct misaligned or damaged holes.

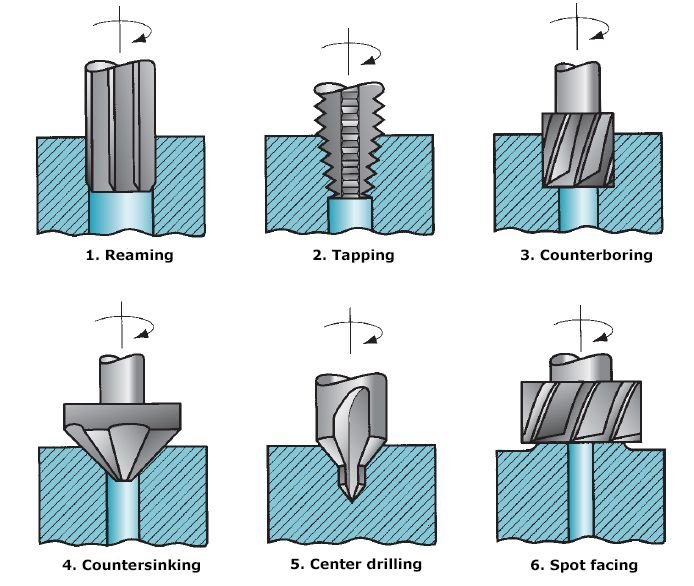

- Tools Used: The process is performed using a counterbore tool, which is a cylindrical cutting tool with a pilot on the end to guide the cutting process. The tool’s diameter is chosen based on the desired final diameter of the hole.

- Process Description: The counterbore tool is aligned with an existing hole, and the pilot of the tool guides it to cut a larger diameter at the top or along the hole. The depth of the counterbore is controlled to ensure consistency.

- Applications: Counterboring finds applications in various industries, including automotive, aerospace, and manufacturing, for creating recesses for bolt heads, accommodating bearings, or ensuring a flat surface for seating washers.

- Advantages: It provides a solution for hiding fasteners and achieving a clean, flat surface. It also helps in aligning components that need to be fastened together.

- Precision and Finish: Counterboring helps achieve precise dimensions and a smooth finish in the cavity created, crucial for the proper fitting of the component being recessed.

In summary, counterboring is a valuable technique in precision machining for creating uniform, flat-bottomed cavities in materials, allowing for better fastener fit and a more aesthetically pleasing surface finish.

Latest Articles in your inbox

Subscribe to our newsletter to get the newest manufacturing and industrial services articles in your inbox once a week.