what is Countersinking?

Countersinking is a machining process designed to create a conical hole that matches the angle of a countersunk screw or fastener. This allows the head of the screw to sit flush with or below the surface of the material. Key aspects of countersinking include:

- Purpose and Application: The primary purpose of countersinking is to ensure that the heads of flat or oval countersunk screws are level with or below the surface of the workpiece. This not only provides a smooth finish but also prevents any snagging or interference that protruding screw heads might cause. It’s commonly used in applications where a smooth surface is crucial, such as in the manufacturing of furniture, aircraft, and other metalwork projects.

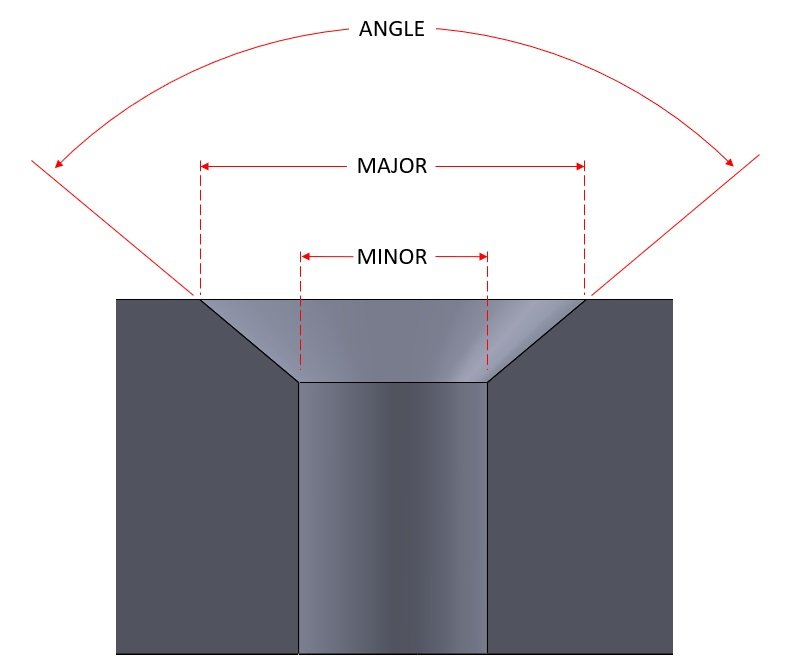

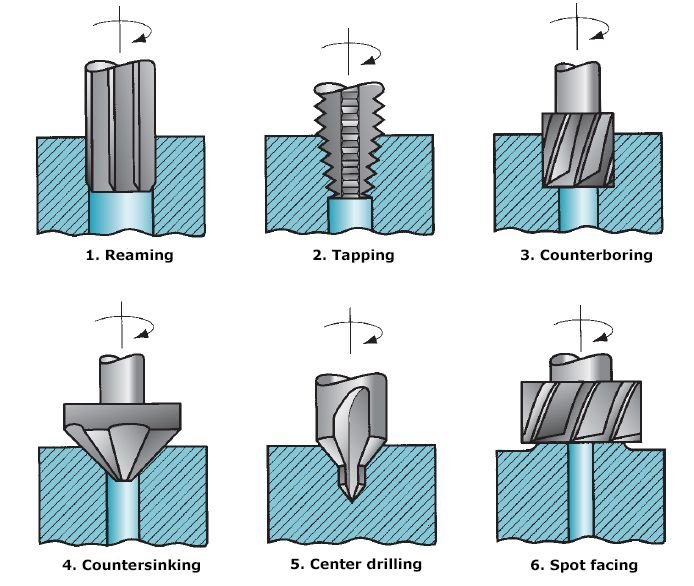

- Tools Used: The process employs a countersink tool, which is a conical-shaped cutting tool. The angle of the countersink tool typically matches the angle of the screw head, with common angles being 82 degrees and 90 degrees for different screw types.

- Process Description: During the process, the countersink tool is applied to an existing hole or directly onto the material surface. The tool cuts a tapered hole that matches the profile of the screw head.

- Material Compatibility: Countersinking can be performed on a variety of materials, including metals, plastics, and wood, making it a versatile process for various industries.

- Advantages: The process not only enhances the aesthetic appeal of the finished product by allowing screw heads to sit flush with the surface but also improves safety by eliminating sharp edges or protrusions.

- Variations and Customization: Countersinking can be customized to different screw sizes and types, ensuring a perfect fit for the fasteners used.

In summary, countersinking is a crucial process in manufacturing and assembly, where it is essential for the proper seating of flat-headed screws, ensuring both functionality and a clean, professional finish in various applications.

Latest Articles in your inbox

Subscribe to our newsletter to get the newest manufacturing and industrial services articles in your inbox once a week.