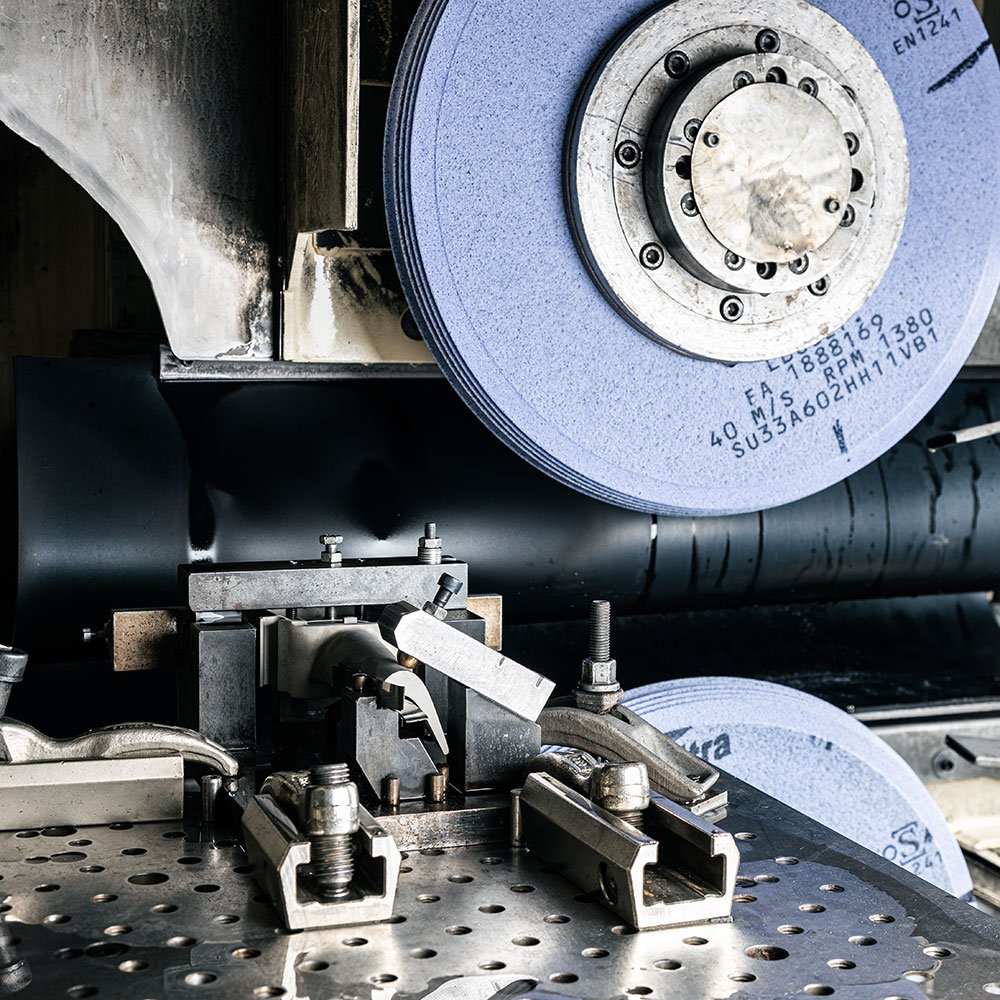

what is Creep-feed Grinding?

Creep-feed grinding is a relatively new process that became the dominant approach in manufacturing aircraft turbine blades in the 1960s and is now known as a cost-effective process in a wide range of metal cutting and removal applications.

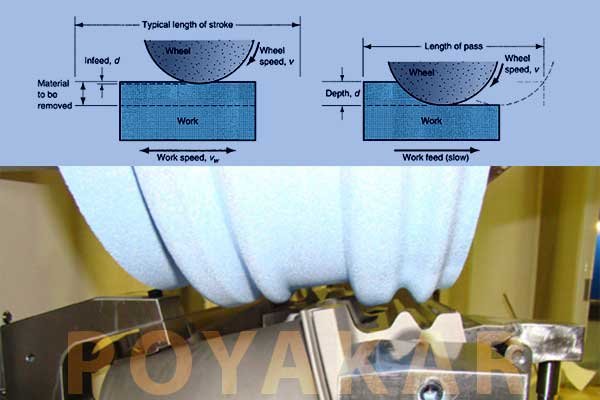

As you may know, in conventional grinding, the process involves the grinding wheel moving back and forth over the workpiece in each pass, removing a very small amount (about 2-25 microns) of material from the surface of the workpiece until it reaches its final size. However, creep-feed grinding is a process where a formed grinding wheel plunges into the workpiece in a single pass, producing the final piece in one stage. Due to the deep cut depth, the feed rate in this process cannot be fast, hence it is called a creep-feed operation. In this process, chips – like in conventional milling – are formed in the contact arc between the wheel and the workpiece. Due to the nature of this grinding, very large forces are generated, requiring machines designed for this purpose to be highly powerful and rigid; meaning that in these grinding machines, the bases and columns will be heavier.

Moreover, the coolant must be carefully controlled to be effectively present in the contact arc – which is generally deep here – to prevent burning of the workpiece surface, thus requiring a high-pressure and high-flow cooling system.

Characteristics of creep-feed grinding

- Shorter cycle times

- Good repeatability

- Tight tolerances

- Improved fatigue resistance

- The ability to machine superalloys and fully hardened materials

- Burr-free surfaces

- Much better surface smoothness

Advantages of creep-feed grinding

- Increases the capability and quality of parts with grooves or profiles.

- Eliminates costly initial operations like milling, broaching, or turning. This process can grind grooves or profiles in full depth (i.e., without any need for preliminary machining operations).

- Eliminates the need for stress-relieving operations after milling and heat treatment and before conventional grinding.

- Reduces production time and cost: For example, the conventional machining process for a part might require milling, deburring, heat treatment, stress relieving, and reciprocating grinding, whereas with creep-feed grinding, milling, deburring, and stress relieving can be eliminated.

- Reduces setup (tuning) costs and times.

- Reduces tooling costs (e.g., form milling tools, and broaching tools compared to grinding wheels).

- Increases the number of parts produced per grinding wheel life. The wear and tear of these types of wheels is less compared to reciprocating grinding wheels.

- Reduced dressing frequency of grinding wheels due to the use of softer wheels.

- The form of the grinding wheel lasts longer, thus reducing the frequency of dressing and consequently increasing productivity.

- Reduced grinding wheel costs due to less wear and fewer dressing requirements, improved tolerances, and better surface integrity compared to milling, broaching, and turning.

- No subsurface stresses.

- Increased machine life due to fewer grinding passes and reduced wear on the machine’s support table.

- Some applications of creep-feed grinding in manufacturing processes include grinding of internal and external cylinders, semi-cylindrical surfaces such as turbine blade root forms, interrupted surfaces like milling cutters, helical forms such as threads and drill flutes, cam grinding, and gear grinding.

Creep-feed grinding is astonishingly becoming widespread. It’s nothing like conventional grinding. The best description for it is milling, but using a grinding wheel instead of a milling cutter. Essentially, creep-feed grinding uses an aluminum oxide, porous glass-bonded wheel to make cuts ranging from 1 millimeter to over 25 millimeters. This process is specifically used in the aerospace industry and other industries that use hard-to-machine alloys.

A typical creep-feed grinding wheel removes more raw material in one or two hard passes, followed by a grinding pass, to finish with an accuracy of 25% millimeter in size and 0.005/0 millimeter in form with minimal burr.

Furthermore, the part must be cool at the end of the cycle. This process is done on most materials in heavy-duty grinding machines resistant to heat and wear, and has a high potential for fine and intricate components, with a tendency to harden.

This technology, which originated in Europe, spread slowly. It was found that hard steel tools should be softened by eliminating the soft milling stage and then ground. (Just in one or two stages). It was noted that the material removal rate is often equal to or better than those achieved by milling at a lower cost per part. Additionally, there are more benefits in complete surface grinding compared to milling. Post-grinding operations such as burr removal and finishing are significantly reduced or even eliminated. Creep-feed grinding is no longer limited to the aerospace industry but is more common in steel, steel parts, and stainless steel applications, and its uses in aluminum, titanium, and magnesium sectors are expanding.

Latest Articles in your inbox

Subscribe to our newsletter to get the newest manufacturing and industrial services articles in your inbox once a week.