what is Reaming?

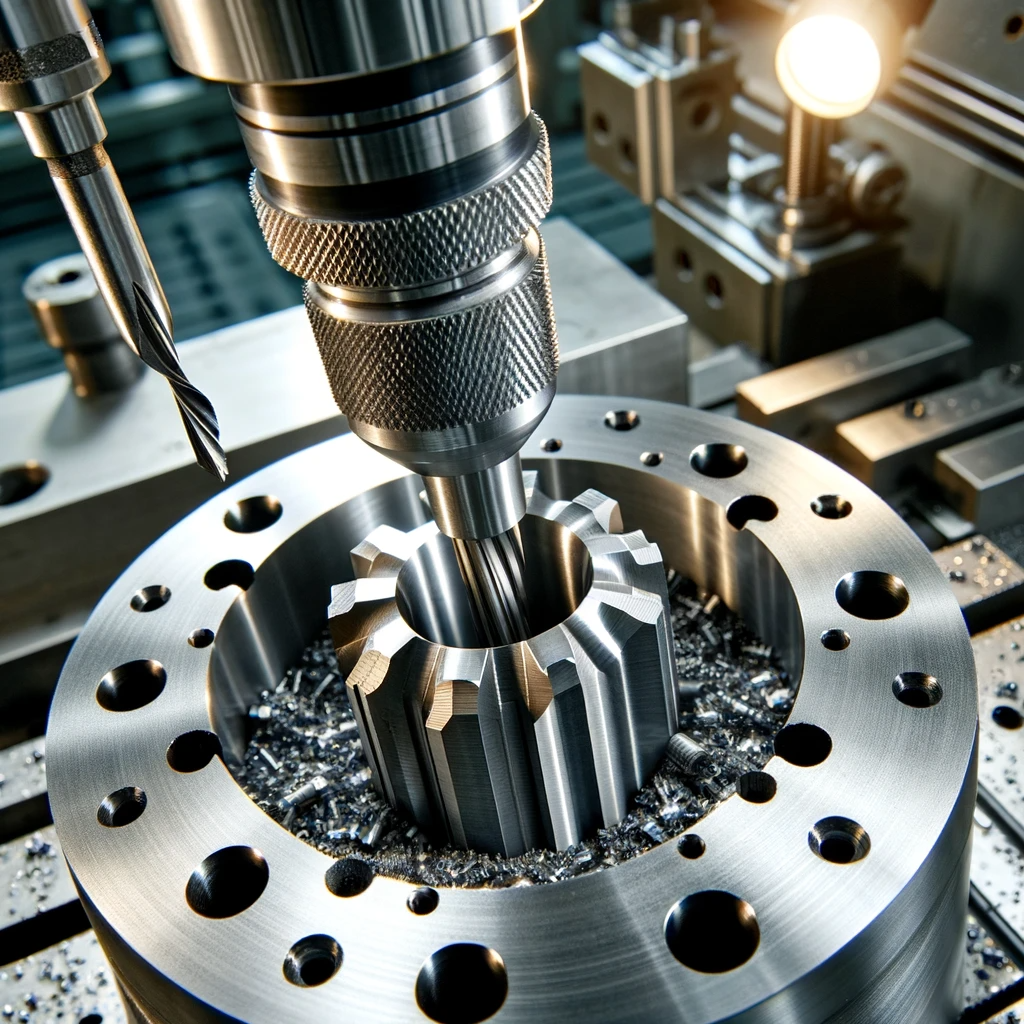

Reaming is a machining process used to improve the accuracy and finish of a hole that has already been drilled, bored, or otherwise formed. The process involves using a tool called a reamer, which has multiple cutting edges. Here are some key aspects of reaming:

Precision and Finish: Reaming is primarily used to enhance the precision of a hole’s diameter and to produce a smoother internal surface finish. This is crucial in applications where tight tolerances and smooth finishes are required.

Reamer Tool: A reamer tool is a type of cutting tool used in machining, specifically designed for enlarging and finishing pre-drilled holes to a precise size and smooth finish. Typically, reamers have multiple cutting edges along their cylindrical body and may have a tapered or straight design. They can be used in machines like drill presses or lathes or even operated by hand, depending on the precision and finish required. The operation involves the reamer entering an existing hole and removing a small amount of material to achieve the desired diameter and surface finish.

Sizing: Reamers are used to slightly enlarge the size of a hole, typically by a very small amount (usually under 0.5mm or 0.020 inches). They are not meant for removing large amounts of material.

Types of Reamers: There are several types, including hand reamers, machine reamers (like chucking and bridge reamers), and shell reamers. Each type has specific applications and is designed for certain materials and hole sizes.

Application: Reaming is used in metalworking, woodworking, and manufacturing industries for applications like fitting bearing races, dowel pins, or precision fasteners.

Coolants and Lubricants: Like other machining processes, reaming often requires coolants or lubricants to reduce heat and wear on the tool and workpiece.

Limitations: Reaming is generally not suitable for significantly enlarging holes or creating holes from solid material; it’s mainly for finishing and minor size adjustments.

Overall, reaming is a critical finishing operation in precision machining, offering control over hole size and surface quality, which is essential in high-tolerance engineering applications.

Latest Articles in your inbox

Subscribe to our newsletter to get the newest manufacturing and industrial services articles in your inbox once a week.