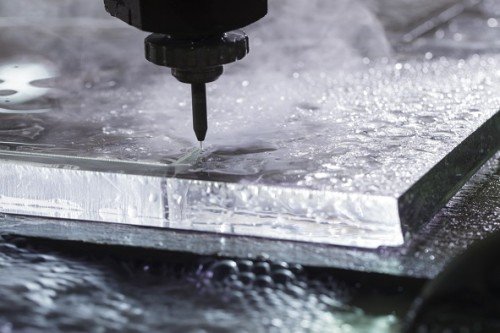

what is Water Jet Cutting?

A waterjet device or water cutting is a tool used for cutting metals or other materials like stone and granite. In a waterjet machine, a thin stream of plain water or a mixture of water and abrasive substances such as aluminum oxide or garnet is used, which exits at very high speed and pressure (for example, 400 MPa) through a small orifice.

When the materials to be cut are sensitive to heat, water cutting is preferred. Some waterjets use pure water (without abrasive materials) for cutting, which are suitable for softer materials like food, rubber, and foam. By changing the nozzle components and the type and size of the abrasive materials, the width or kerf of the cut can be altered. In standard abrasive cuts, the width of the cut is between 0.04 to 0.05 inches (1.016 to 1.27 millimeters) but can be as narrow as 0.508 millimeters.

In non-abrasive cutting, the normal cut width ranges from 0.178 to 0.33 millimeters but can be as small as 0.076 millimeters, which is approximately the thickness of a human hair. These very fine jets can be used to create very precise cuts for a wide variety of applications.

Latest Articles in your inbox

Subscribe to our newsletter to get the newest manufacturing and industrial services articles in your inbox once a week.